Hyundai to Mass-Produce 30,000 Atlas Humanoids Annually by 2028

Hyundai Motor Group unveiled an ambitious plan at CES 2026 to industrialize humanoid robotics production, promising to integrate Boston Dynamics machines into its factories and sell robot services via subscriptions. The move could reshape manufacturing, logistics and labor markets by embedding AI-driven, upgradable robots across global operations.

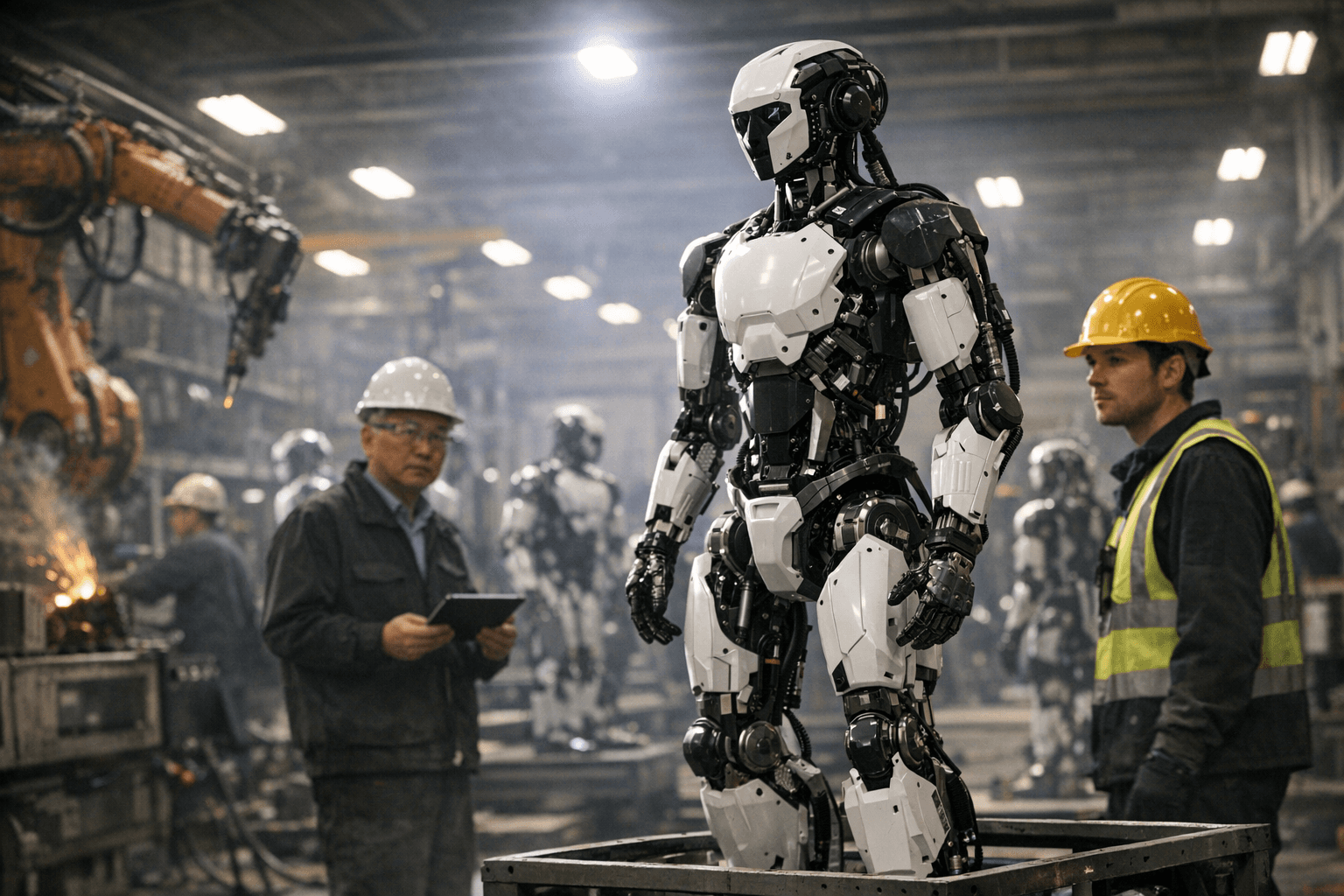

Hyundai Motor Group announced at CES 2026 a sweeping strategy to scale humanoid robotics from demonstration labs into industrial reality, aiming to produce 30,000 Boston Dynamics Atlas robots per year by 2028. The plan centers on a high-tech manufacturing hub near Savannah, Georgia, described as a “Metaplant,” where Hyundai expects to begin deploying Atlas units in its production complex in 2028.

The company said it will stitch together Boston Dynamics’ robotics expertise with Hyundai’s manufacturing, logistics and parts affiliates, including Hyundai Mobis and Hyundai Glovis, creating what it calls an AI Robotics Value Chain. That chain will rely on partnerships with AI firms such as Google DeepMind and NVIDIA to supply simulation libraries, AI infrastructure and software-defined factory tools. Hyundai plans a Robot Metaplant Application Center to teach robots using real-world production data and to validate safety for human-robot collaboration.

Initial deployments will focus on tasks with clear safety and quality advantages. Hyundai plans to start with parts sequencing at the Savannah plant in 2028 and to train Atlas to assemble vehicle components by 2030. Over time the company intends Atlas to take on repetitive, heavy or higher-risk operations as performance and safety are validated. Hyundai framed the initiative as part of a broader push into “physical AI,” meaning AI embedded in hardware that collects real-world data and makes autonomous decisions across robotics, smart factories and autonomous driving.

Hyundai described Atlas as capable of lifting about 110 pounds, operating autonomously and being trained for most tasks in less than a day. The group already deploys Boston Dynamics machines in industrial settings: Spot, a quadruped, is used for data collection and safety monitoring at the Savannah site, and Stretch, a warehouse robot, has moved millions of boxes globally since its introduction.

A key commercial element of the strategy is an expansion of Robotics-as-a-Service. Hyundai intends to offer subscription plans so customers can use robots without buying units outright, integrating hardware, software, maintenance and upgrades into recurring-service contracts. Hyundai did not disclose the per-unit cost of Atlas in its CES statements.

The program is backed by large investment commitments intended to accelerate robotics and electrification. Hyundai announced multibillion-dollar investments to develop AI-powered robotics, including sizable planned spending in Korea and in the United States. The group also named organizational leads for the effort, including Carolina Parada as Senior Director and Head of Robotics and Zachary Jackowski as General Manager — Atlas.

The announcement sharpened discussion about the future of industrial work. Hyundai acknowledged worker concerns about job losses and said deployments will be phased and tied to validated safety and quality benefits. Company leaders emphasized that humans will remain necessary to maintain and train robots and that new roles will emerge as deployments scale. At the same time, the plan positions Hyundai more directly against rivals pursuing humanoid designs and accelerates competition in a nascent market where technical capability, cost and safe integration will determine commercial success.

Sources:

Know something we missed? Have a correction or additional information?

Submit a Tip