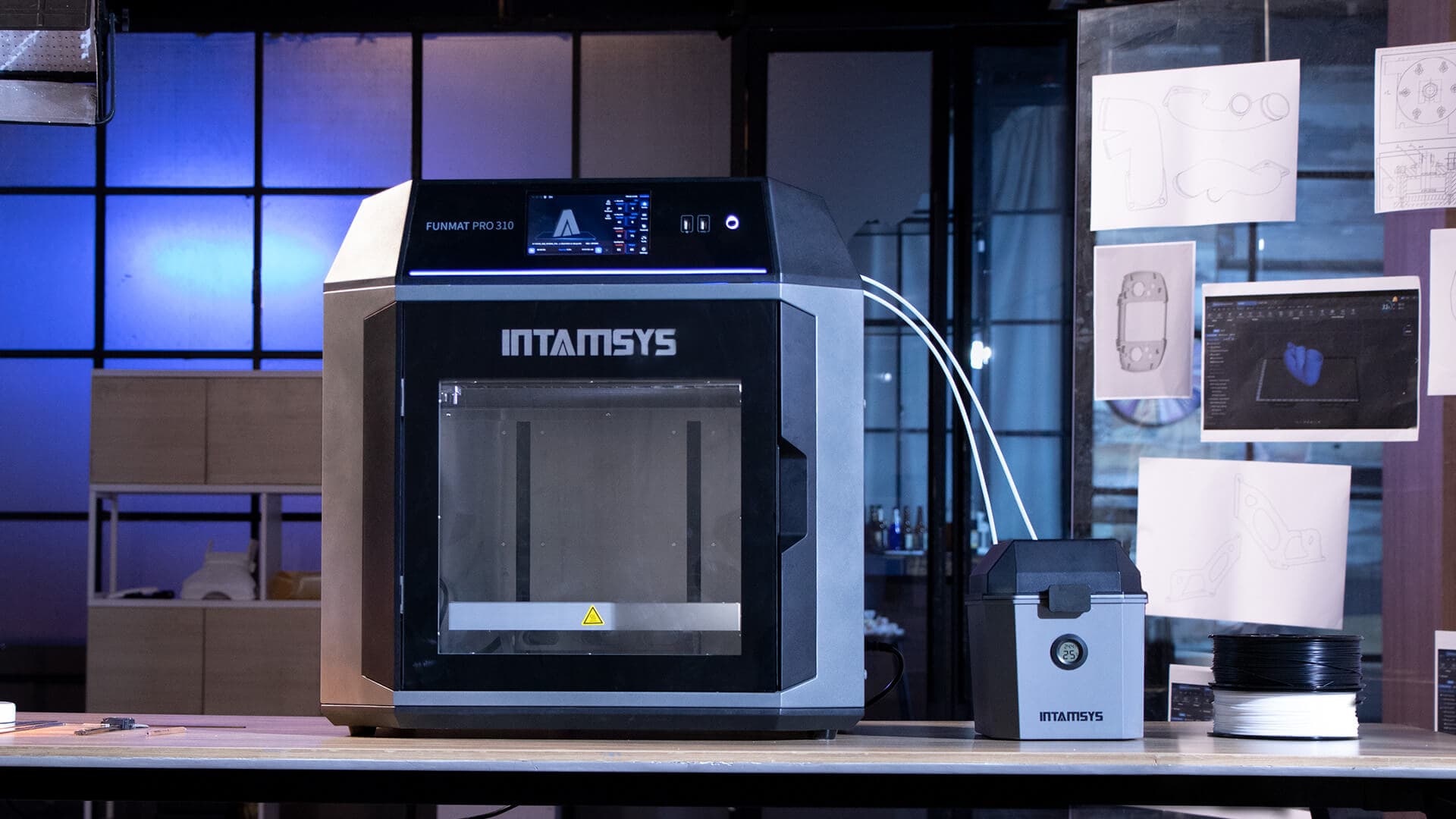

INTAMSYS Unveils FUNMAT PRO 310 APOLLO, Scaling PAEK Production

INTAMSYS launched the FUNMAT PRO 310 APOLLO at Formnext in Frankfurt, positioning the company to push fused filament fabrication into continuous, industrial production of high-performance PAEK polymers. This development matters because broader, faster printing of PAEK such as PEEK could shift supply chains for aerospace, medical and energy sectors that require heat resistant, high strength parts.

INTAMSYS, a longstanding player in industrial fused filament fabrication, unveiled its next generation high performance materials printer, the FUNMAT PRO 310 APOLLO, at Formnext in Frankfurt on November 18, 2025. The company presented the machine as designed to enable continuous production runs using PAEK family polymers, a class that includes the widely used PEEK and is prized for its high temperature resistance, chemical durability and mechanical strength.

Over the past decade, FFF printing has evolved from a rapid prototyping tool to a method for producing end use components. INTAMSYS has been among the vendors promoting that shift, and with the APOLLO it is aiming to tackle two persistent barriers to industrial adoption of PAEK materials: throughput and reliable material performance during long production cycles. The company framed the printer around high speed production and high strength output, targeting sectors where component performance and lifecycle durability are essential.

PAEK polymers are semi crystalline thermoplastics that demand controlled thermal conditions during printing to achieve predictable mechanical properties and dimensional stability. Manufacturers that adopt additive production for these materials must manage precise extrusion temperatures, chamber temperatures, and crystallization behavior to meet engineering standards. The promise of a machine marketed for continuous PAEK production therefore carries implications for qualification, quality assurance and part certification in regulated industries.

If the APOLLO delivers on its stated aims, the device could alter supply chain dynamics for industries that have long relied on machined metal or injection molded polymers. Aerospace suppliers, medical device makers and energy sector firms often need components that perform in extreme environments while keeping weight and assembly complexity down. Additive production of certified PAEK parts at higher volumes could shorten lead times, enable more localized manufacturing, and support design consolidation that reduces assembly steps.

However, broader adoption is not guaranteed by a single product release. Industrialization will hinge on material qualification protocols, repeatable process documentation, and third party certification for safety critical uses. It will also require trained operators and updated testing regimes to ensure that parts printed continuously maintain consistent microstructure and mechanical properties over large builds and multiple shifts.

The environmental equation is also complex. High performance polymers consume significant energy during processing, and the life cycle benefits of additive manufacturing depend on application specific weight savings, part consolidation and service life improvements. Recycling pathways for PAEK materials remain limited compared with commodity polymers, adding another consideration for manufacturers assessing the switch.

INTAMSYS’s announcement underscores how the boundaries of filament based 3D printing continue to expand. By targeting continuous production with materials traditionally confined to small batch or prototype use, the FUNMAT PRO 310 APOLLO embodies the next stage of industrial additive ambitions. Whether it will accelerate certified, high volume PAEK printing will depend on how the industry addresses qualification, certification and sustainability at scale.