OSHA Tools Offer Young Worker Safety Guidance for McDonald's Employees

Federal workplace safety resources from OSHA provide targeted guidance for young restaurant workers, addressing common kitchen and customer facing hazards and explaining how to report serious dangers. The materials include training modules, videos and checklists that franchise owners, managers and corporate safety teams can adapt to reduce injuries and strengthen on shift training.

OSHA has assembled a suite of national resources aimed at protecting younger workers in restaurants, a category that includes a large share of McDonald’s crew members. Central to the package is the Young Worker Safety in Restaurants eTool, accompanied by practical materials that outline common hazards in both kitchen and customer facing roles. The guidance covers prevention strategies for burns, slips, trips and falls, and cuts, and it addresses safe use of equipment as well as techniques for handling violent or abusive customers.

The resources are organized to be usable by employers and by the young workers themselves. Training modules, online videos and checklists are designed for managers and supervisors to improve on shift training and reduce the risk of injury. That training content is intended to support routine tasks and difficult interactions alike, so employees learn both the mechanical safety steps and de escalation approaches for hostile situations with customers.

OSHA also provides information about how workers and supervisors can file complaints and request workplace inspections when serious safety hazards are present. Those reporting channels give employees a formal path to escalate unresolved dangers, and give employers a framework for correcting problems that could otherwise lead to accidents or regulatory action.

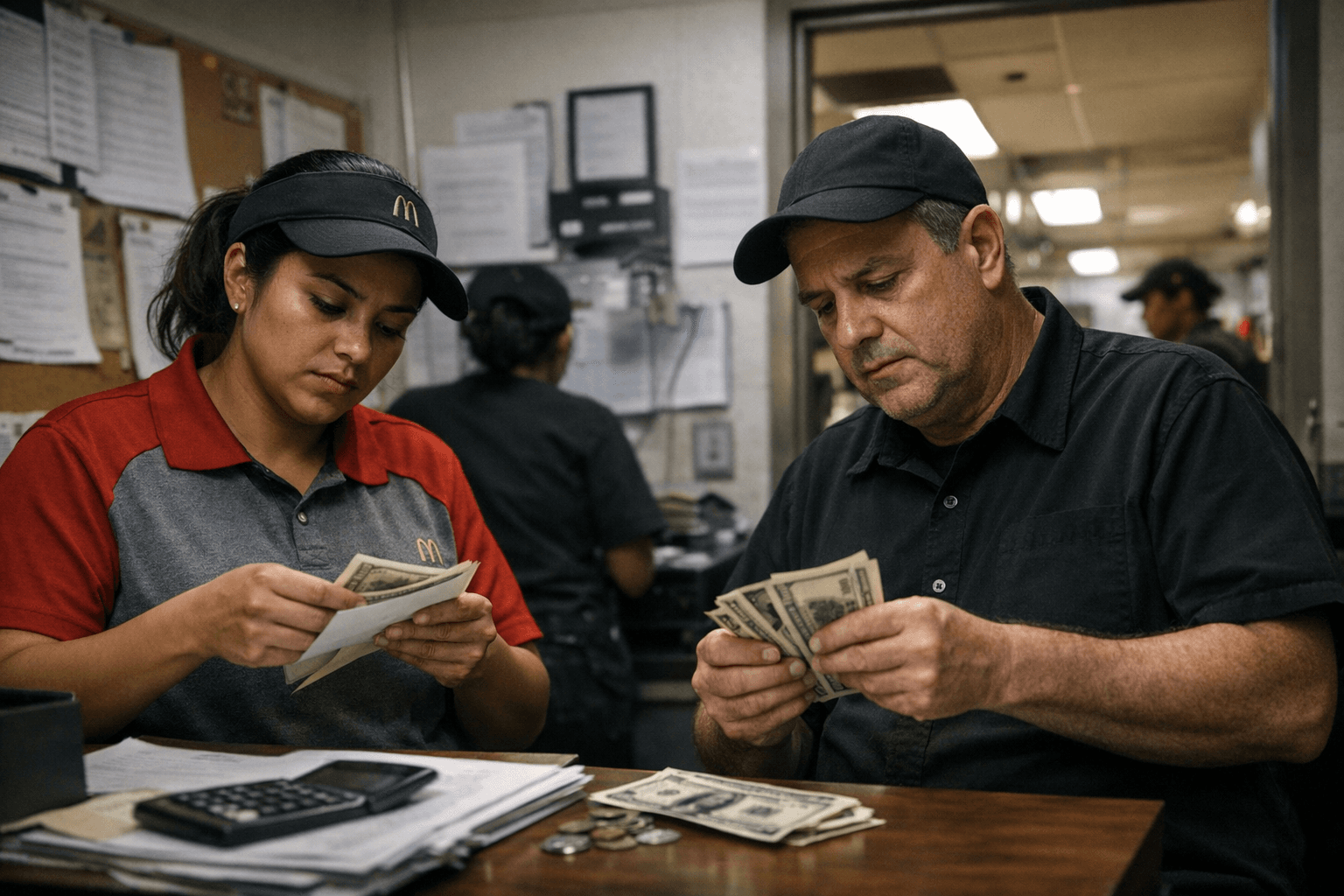

For McDonald’s franchise owners and store managers, the resources offer ready made, government published materials that can be incorporated into local safety programs and orientation curricula. Corporate safety teams may find the checklists and training modules useful for standardizing expectations across locations and for documenting training efforts. Better on shift teaching and clearer reporting routes can reduce injury rates, lower absenteeism and help retain young employees who might otherwise leave after a bad safety experience.

Adoption will require adapting the materials to specific store layouts, equipment and local policies, and committing manager time to consistent training. For a chain that relies heavily on younger workers, using these OSHA tools can improve daily safety, clarify incident reporting, and support a more stable frontline workforce.

Sources:

Know something we missed? Have a correction or additional information?

Submit a Tip