Compact Metal Paste 3D Printer Targets Offices and Labs

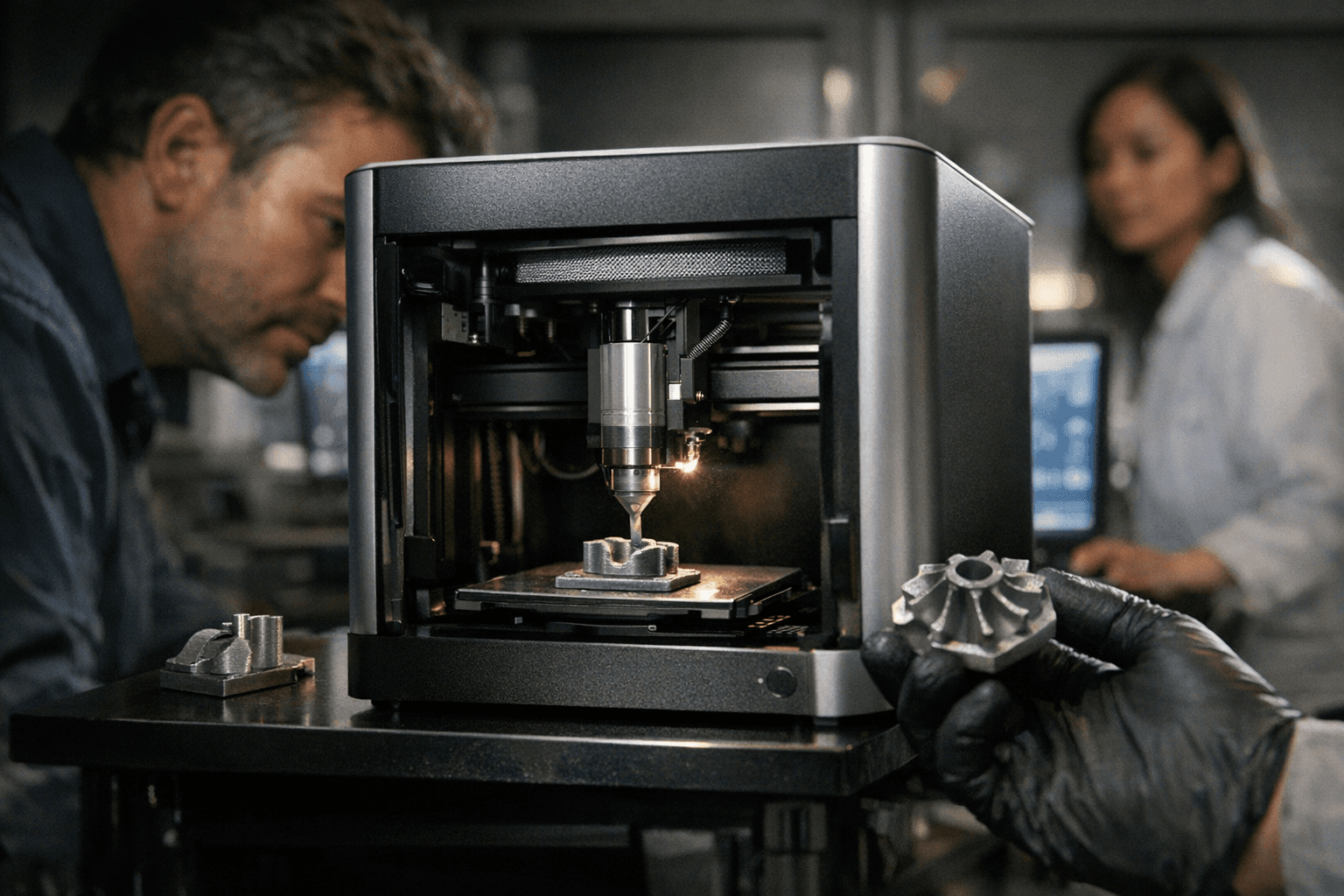

Korean company MetalPrinting unveiled the Gauss MT90 at CES 2026, a compact metal paste 3D printer that replaces powder and laser systems with Paste-based Metal Extrusion (PME). By removing loose metal powder and high-temperature welding steps and adding a built-in HEPA filter and AI-driven viscosity control, the MT90 aims to bring lower-energy, lower-risk metal additive manufacturing into office and lab environments.

MetalPrinting introduced the Gauss MT90 today at CES 2026, positioning the machine as a desktop-capable metal additive manufacturing system designed for settings where powder handling and laser welding present cost, energy, or safety barriers. The MT90 prints from metal paste formulations rather than metallic powders, removing a major source of regulatory and occupational complexity while keeping support for common engineering alloys.

The MT90 offers a 420 × 420 × 500 mm build envelope, large enough for many functional prototypes, tooling components, and small production runs. Metal paste formulations are available for aluminum, copper, titanium and 316L stainless steel, broadening material options for conductive, thermal, and structural applications without the need for powder management systems.

To maintain consistent extrusion, the MT90 integrates an AI camera-based viscosity unit and extrusion-control algorithms that monitor paste behavior and adjust feed parameters in real time. Combined with Quick Start process presets, LED status signaling and a magnetic door, the system emphasizes ease of use and reduced operator training. An automatic bed-replacement system targets continuous production workflows, allowing users to swap build plates without lengthy downtime.

Safety and indoor compatibility are central to the MT90 design. The machine omits loose metal powder and high-temperature laser steps that typically require specialized ventilation and filtered enclosures. A built-in HEPA filter further manages emissions, making installation in offices, design studios, university labs and shared maker spaces more feasible than with traditional powder- or laser-based metal printers. MetalPrinting positions the MT90 as a lower-energy, lower-risk alternative to conventional metal additive methods, which may lower facility upgrade costs and speed deployment.

For practitioners, the practical value is clear: the MT90 could shorten metal prototyping cycles, enable closer iteration between design and physical testing, and reduce the logistics of material handling. The broad material support opens possibilities for conductive parts and corrosion-resistant components, while AI-assisted extrusion and automatic bed swaps reduce operator intervention for longer runs.

Verify material compatibility and post-processing requirements for your intended parts, and plan for any necessary sintering, heat treatment or finishing steps after paste extrusion. Expect interest from small manufacturers, research labs and product development teams looking for a safer, more accessible route into metal additive manufacturing.

Sources:

Know something we missed? Have a correction or additional information?

Submit a Tip