AMIS Adds Adaptive Variable Slice Heights to Binder-Jet Workflows

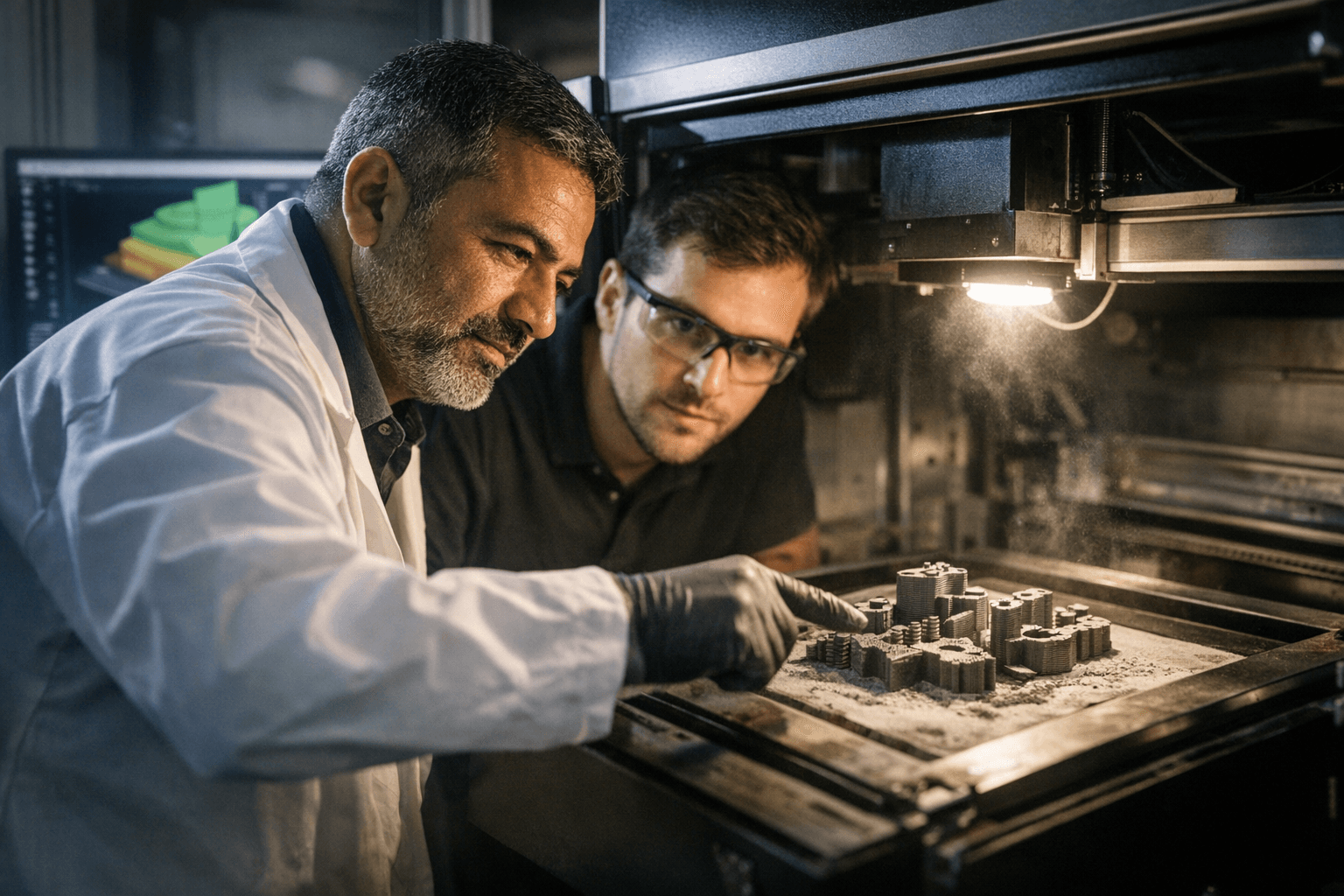

Belgium-based AMIS partnered with Dr. Hasan Bas and the Advanced Manufacturing research center at Ondokuz Mayıs University in Turkey to integrate an adaptive, variable-slice-height algorithm into AMIS Pro for binder-jet printing workflows. The change reduced layer counts in tests by roughly 12 percent and aims to cut build time while improving surface finish and dimensional fidelity.

AMIS announced integration of a new adaptive slicing algorithm into AMIS Pro that targets binder-jet production workflows. Developed in partnership with Dr. Hasan Bas and the Advanced Manufacturing research center at Ondokuz Mayıs University, the algorithm combines binder optimization with variable layer heights so the software prints thinner layers where models require fine detail and thicker layers where geometry is simple.

In validation tests, AMIS reported about 12 percent fewer layers overall compared with uniform slice heights, a reduction that directly translates into shorter build times for many parts. The company also highlighted improved surface finish and a reduced staircase effect, outcomes that can lower post-processing labor for surface smoothing and dimensional corrections. AMIS framed the work as an efficiency and quality step for binder-jet production workflows and described the integration as moving toward faster, smarter binder-jet manufacturing.

The technical change addresses a familiar limitation in layer-based printing: uniform slice heights force a trade-off between detail and speed. By adapting layer thickness to local geometry and aligning binder deposition parameters with those changes, AMIS Pro aims to preserve dimensional fidelity while reducing the number of passes required to build a part. For users, that means potential savings in machine hours and less time spent sanding or finishing parts where the staircase effect previously created visible steps on sloped surfaces.

Practical implications vary by machine, material, and part geometry. Test results provided by AMIS show promising reductions in layer count, but users should validate outcomes on their specific printers. Test the updated slicer on representative parts and measure dimensional accuracy, surface quality, and material usage before deploying it in production runs. Pay attention to how adaptive layers interact with binder saturation and curing, and adjust binder settings where necessary to maintain mechanical properties.

The integration into AMIS Pro makes the capability accessible to customers through the existing software platform, so shops and makers using AMIS Pro can evaluate the feature without changing core toolchains. For small shops and university labs that run mixed batches of parts, adaptive slicing can reduce total build time and the amount of finishing required across a build plate. Check AMIS Pro release notes and update channels for availability details and testing recommendations, and plan a short qualification run to confirm the algorithm’s benefits for your workflows.

Sources:

Know something we missed? Have a correction or additional information?

Submit a Tip