Beehive Validates 3D-Printed 200 lbf Frenzy Engine for Flight

Beehive Industries completed high-altitude vacuum-chamber testing of its 200 lbf (≈890 N) Frenzy engine on December 31, 2025, confirming ignition and performance across the engine's intended flight envelope. The results clear a path to scaled production and integration with an initial flight vehicle, with flight testing targeted for Q1 2026—a milestone for additive manufacturing in propulsion.

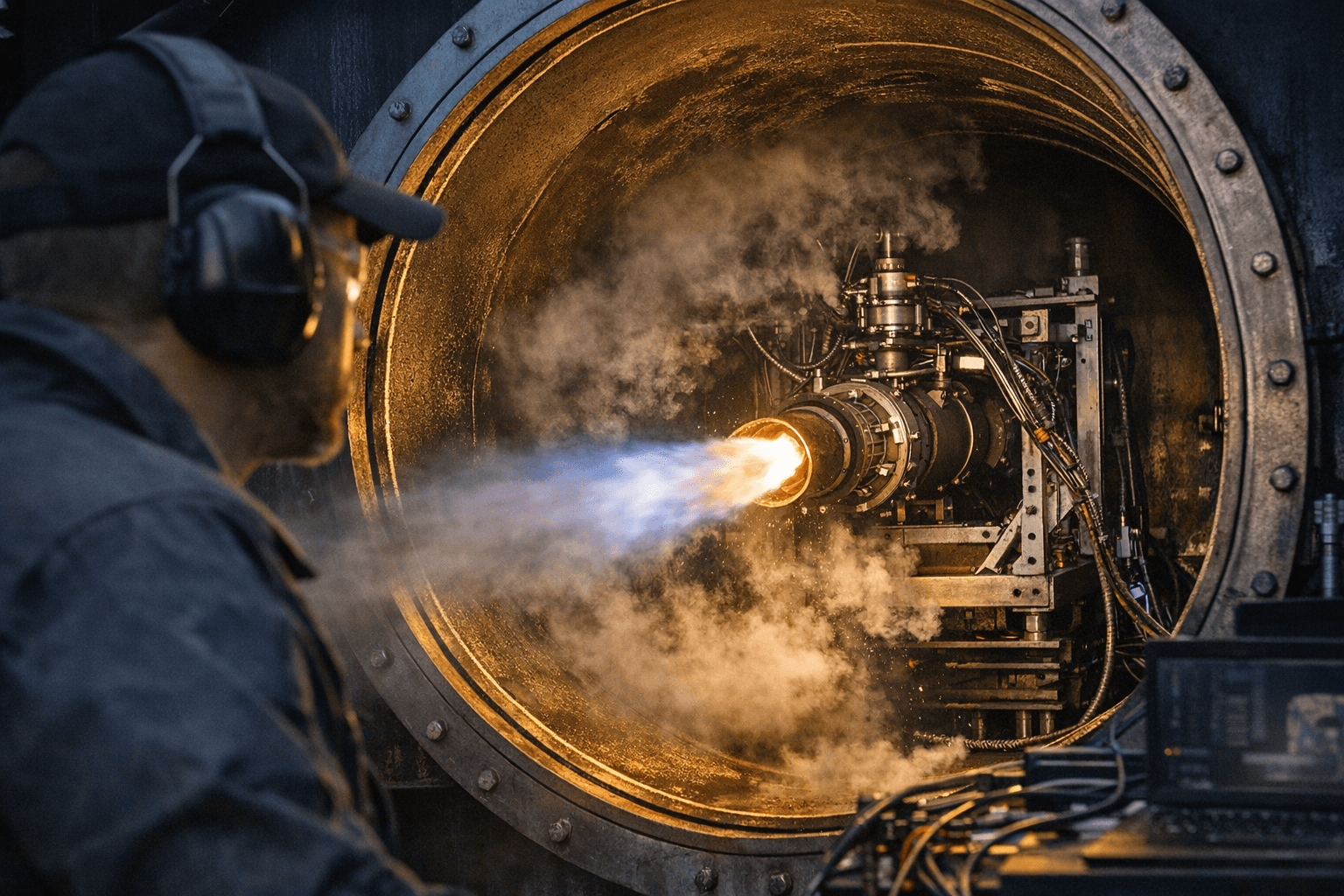

Beehive Industries announced completion of a vacuum-chamber test campaign at a government test facility in Ohio that validated its Frenzy engine under high-altitude conditions. The 200 lbf (approximately 890 N) propulsion unit, manufactured using additive methods, demonstrated reliable ignition and met performance targets across the flight envelope the company designed it for. Company leadership reported that the engine met or exceeded U.S. Air Force requirements during testing and highlighted the rapid development cadence from concept to validated hardware.

The vacuum-chamber work replicates the low-pressure environment an engine sees at altitude and is a standard step before integrating propulsion into flight vehicles. By proving operation under those conditions, Beehive has removed a major technical hurdle and can now focus on production scaling and hardware integration. The company plans to mate Frenzy to an initial flight vehicle and aims to conduct that flight test in the first quarter of 2026.

For the 3D printing and small launch community, this represents a concrete advancement in additive-manufactured propulsion. A validated, small-lift engine built with additive methods shows that printers and post-processing workflows can meet the stringent demands of ignition, chamber pressures, and thermal loads required for flight. That has practical implications for designers and shops considering in-house propulsion development, supply chain partners evaluating manufacturing investments, and operators seeking lower-cost, rapidly iterated engines.

Expect close attention on the upcoming flight test. Flight data will reveal how ground-validated performance translates to integrated-system behavior, including throttle response, thermal management in real-world conditions, and component longevity across cycles. Those metrics will also inform certification pathways for customers in civil and defense markets and affect procurement timelines where the U.S. Air Force requirements already played a role in validation.

Beehive’s move to scale production indicates attention to repeatability and supply chain readiness, not just prototype demonstration. That shift matters for service bureaus and small manufacturers that may supply printed components, finishing, or inspection services. Watch for details on production volumes, inspection regimes, and any announced partnerships that will clarify how additive manufacturing will be used at scale in propulsion.

The Frenzy program underscores that additive manufacturing is advancing from laboratory demos to flight-ready hardware. The immediate next milestone is the planned Q1 2026 flight test, which will determine how quickly Frenzy can transition from validated engine to operational product in both commercial and government applications.

Sources:

Know something we missed? Have a correction or additional information?

Submit a Tip