Creative3DP’s ExtrudeX brings low-cost filament recycling to makers

Creative3DP launched ExtrudeX, a compact, mostly 3D-printable filament extruder and recycler aimed at hobbyists and small print farms. The device promises a practical path to reuse failed prints and purge waste, cutting filament costs while requiring careful shredding, material sorting, and tuning to achieve repeatable, diameter-stable filament.

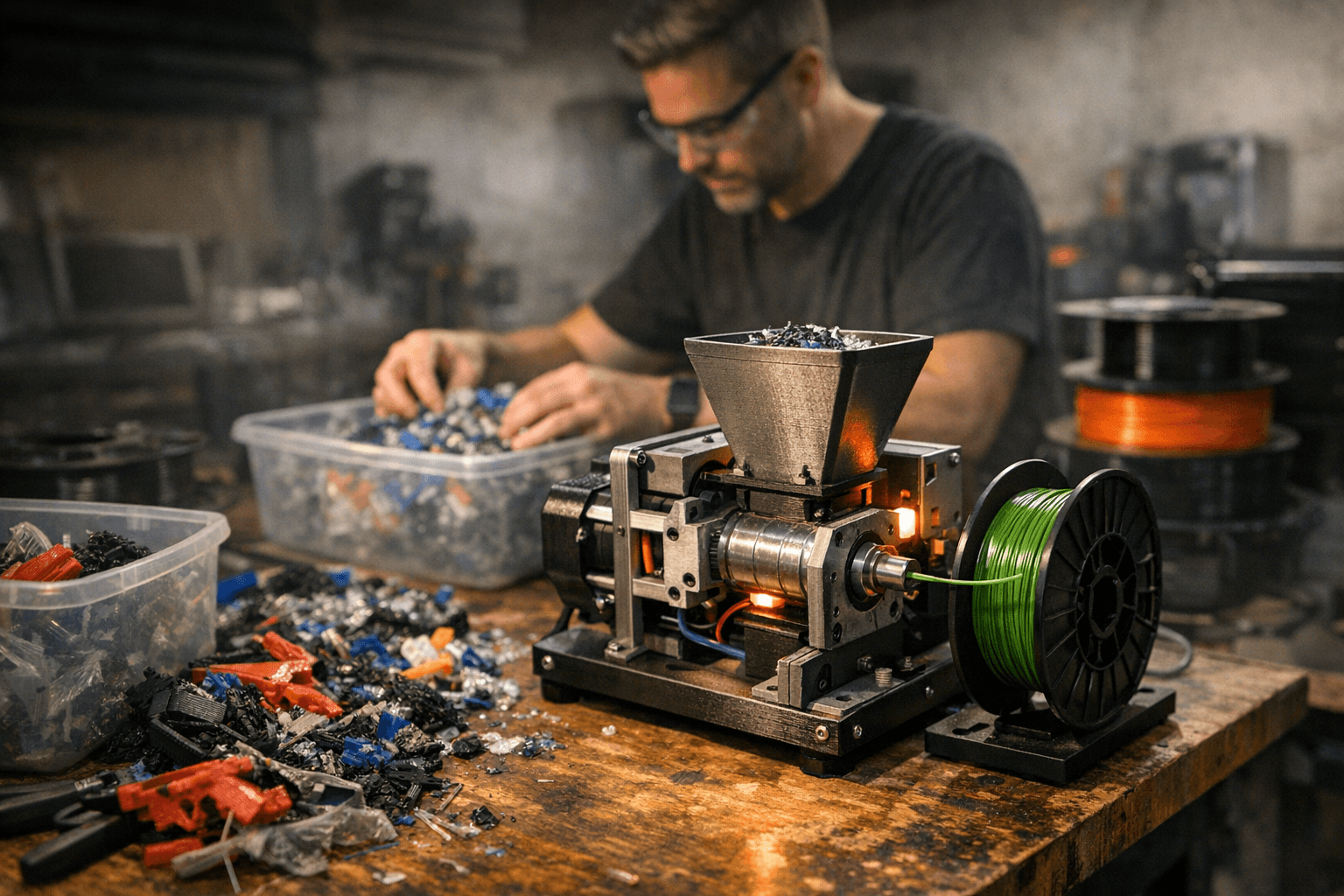

Creative3DP closed a highly successful crowdfunding run and updated BackerKit status on January 1, 2026, for ExtrudeX, a compact filament extruder that combines printed chassis parts with off-the-shelf electronics. Designed for home shops and small production setups, the unit uses a single-screw hot end barrel, a small puller and cooling stage, plus common components such as a DC motor and a PID temperature controller. Because the housing and many structural parts are 3D-printable, the bill of materials is substantially lower than many commercial filament makers.

Operational notes released with the campaign and shared by early testers emphasize practical workflows. For consistent results users found a blend of roughly 60 percent virgin pellets and 40 percent shredded waste produced stable extrusion more reliably than attempting 100 percent recycled material, which produced variable outcomes. Extrusion is started by manually threading the molten strand, then handed over to an automated puller for steady spooling. Optional diameter gauge attachments can be fitted for inline monitoring, though achieving tight tolerances still requires post-processing and experimentation.

Campaign materials outlined multiple pledge tiers, including STL-only packages, commercial license options and combined bundles that pair ExtrudeX with complementary systems such as pelletizers. Component cost estimates provided during the campaign point to significant savings compared with off-the-shelf filament, particularly for makers who already own a shredder and basic electronics. BackerKit tracking showed strong momentum at close, with the campaign far exceeding its funding goal and attracting a large backer base.

Practical value is immediate: the machine gives you a route to turn failed prints, purge waste and support material back into usable filament at a fraction of retail prices. The trade-offs are clear—reliable, diameter-stable filament depends on proper shredding of scraps, strict material sorting to avoid contamination, good drying practices and a period of tuning feed rates and temperatures. Expect to spend time calibrating and post-processing before feeding critical prints.

For users planning to adopt ExtrudeX, plan for a workflow that includes a robust shredder, thorough material labeling and drying, and acceptance that some trial and error will be necessary to match the consistency of commercial filament. The device puts a repairable, maker-friendly recycler within reach for anyone ready to iterate on their filament production.

Sources:

Know something we missed? Have a correction or additional information?

Submit a Tip