Essential One-Page Safety Checklist for FFF 3D Printing

This condensed, practical checklist helps you set up a safer, more reliable FFF (filament) workspace and serves as a one-page reference before printing. Follow straightforward steps on ventilation, electrical safety, fire precautions, filament care, maintenance, print habits, and an emergency plan to reduce fire risk and improve print quality.

A compact checklist can be the difference between a smooth print run and a costly or dangerous mishap. Start by choosing the right location and ventilation. Pick a well-ventilated area or provide local exhaust when printing ABS or other engineering filaments; avoid printing near curtains, paper, solvents, or other flammable materials. For ABS and ASA, prefer an enclosure combined with reduced bed temperature to keep warping down while managing fumes.

Electrical safety is first-line prevention. Plug printers into a dedicated circuit when possible or at least a good surge protector; avoid daisy-chaining power strips. Inspect heated bed wiring and controller boards for frayed insulation, discoloration, or loose connectors and replace any suspect cables immediately. Keep power switches clearly labeled so you can cut power quickly.

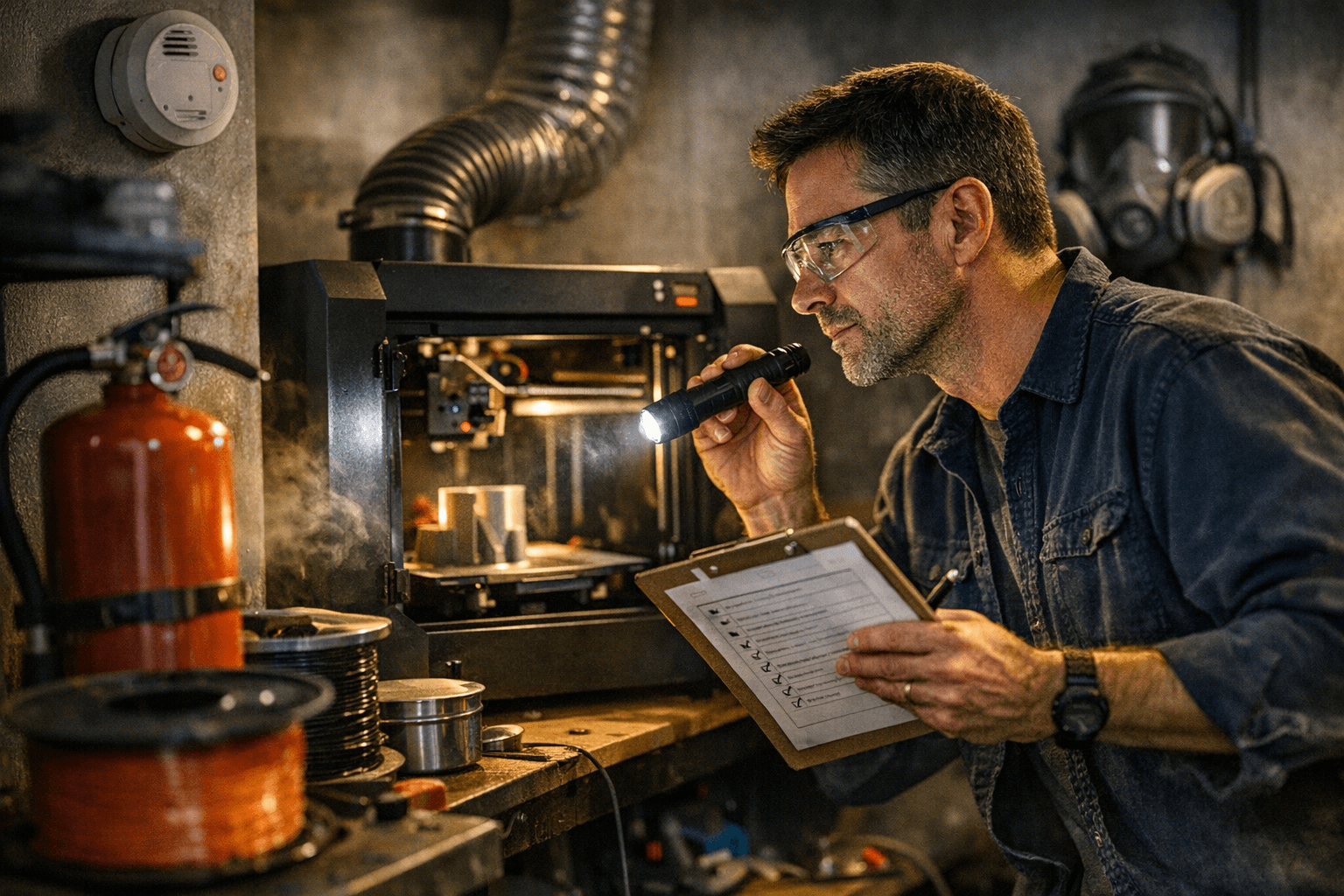

Fire precautions are practical and inexpensive. Place printers on noncombustible surfaces such as a ceramic paver or metal tray and keep a Class ABC or CO2 extinguisher accessible. Do not leave long prints unattended overnight without additional safeguards: install a working smoke detector in the room and consider camera monitoring so you can verify a print has not stalled or caught fire.

Store and handle filament to protect print quality and reduce failures. Keep filament sealed in containers with desiccant and a hygrometer when possible. Dry hygroscopic materials before use: PETG, Nylon, TPU, and PVA benefit from drying at 45–80°C for several hours depending on spool mass and material—this reduces bubbles, stringing, and poor layer adhesion. When switching filament batches, print small test cubes to confirm extrusion behavior and temperature settings.

Routine maintenance prevents failures. Check belt tension and lead screw lubrication regularly, inspect nozzle and hotend condition for wear, and verify electrical connectors are tight. Replace worn hotends and power cables immediately rather than risking intermittent faults.

Refine print habits for the material. Use proper part cooling for PLA to improve surface finish and favor lower bed temperatures and an enclosure for ABS/ASA. Small test prints after setup changes save time and filament by catching issues early.

Finally, have an emergency plan. Label power switches, keep local emergency contact numbers near the workspace, and create a simple room evacuation plan. These steps reduce risk to you and to shared community spaces like makerspaces and workshops, while improving print reliability and saving time. Follow this checklist before long jobs to protect equipment, prints, and people.

Know something we missed? Have a correction or additional information?

Submit a Tip