ML-Designed Printable Aluminum Alloy Shows Fivefold Strength Gain

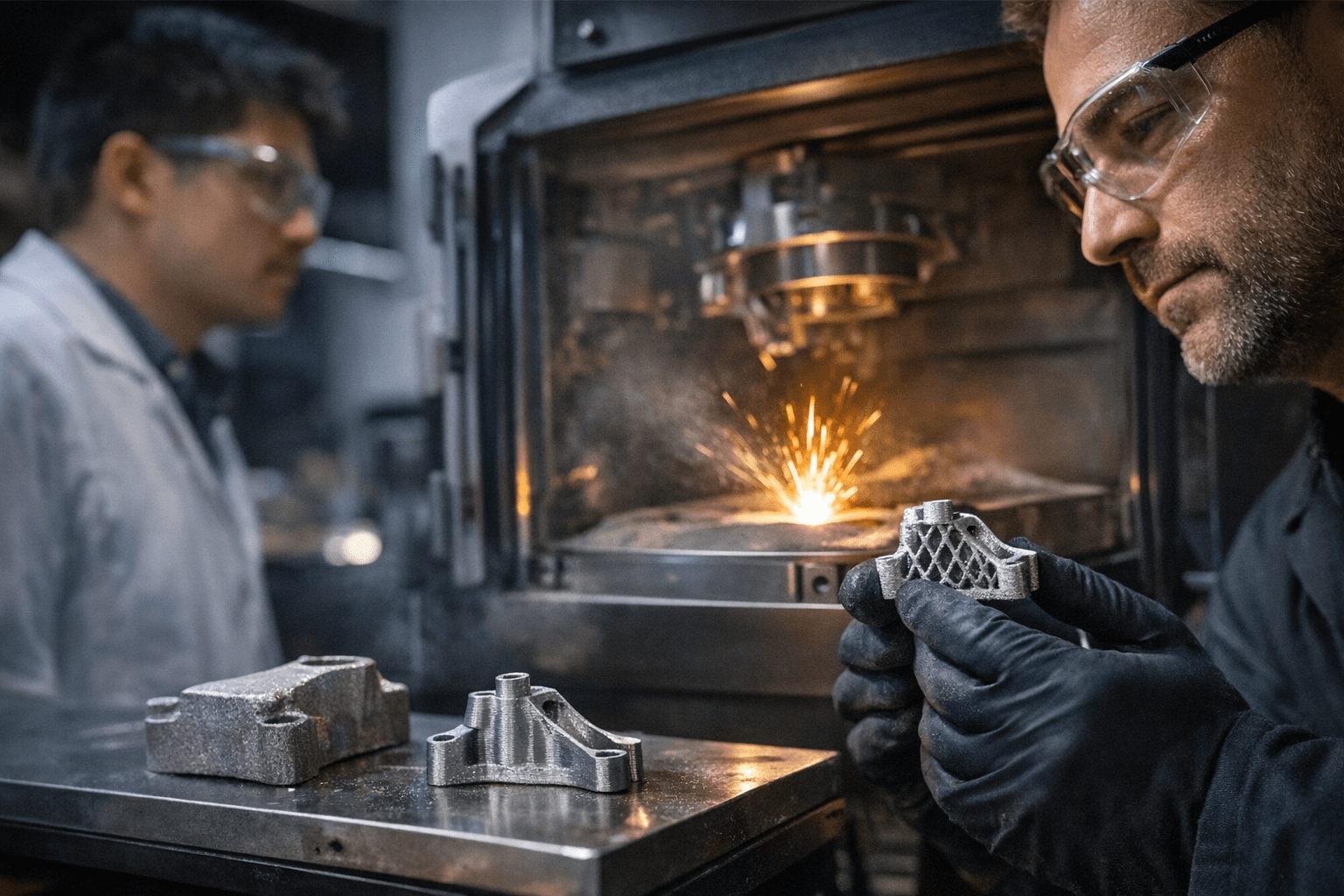

MIT researchers announced a new laser powder bed fusion printable aluminum alloy that demonstrated roughly five times the strength of a cast equivalent and stability up to about 400°C. The team used a hybrid workflow of computer simulation and machine learning to narrow a vast composition space to about 40 candidates, accelerating discovery and producing an alloy with a dense precipitate microstructure that resists coarsening.

On December 29, 2025, a research team at MIT reported a significant advance in metal additive manufacturing: a printable aluminum alloy that combines unusually high strength with high-temperature stability. The alloy, produced by laser powder bed fusion (LPBF), showed strength roughly five times that of a cast counterpart and about 50 percent higher strength than alloys designed using simulation-only methods.

Researchers reached this result by combining physics-based computer simulations with machine learning to screen composition and processing space far more quickly than conventional approaches. The conventional search would have required more than a million simulations. The hybrid method focused the search to roughly 40 candidate compositions, enabling the team to identify a composition whose microstructure yields a very high volume fraction of small, closely packed precipitates. That precipitate morphology drives the alloy's exceptional strength and resistance to thermal coarsening, keeping the microstructure stable up to approximately 400°C.

The team validated their machine-learning-driven predictions through collaborative fabrication and testing. Partners printed test samples by LPBF and sent them back to MIT for mechanical testing and microstructural analysis. Measured properties matched the predicted performance, strengthening confidence in the workflow and in the alloy's applicability for demanding environments.

Practical implications for the 3D printing community are immediate and tangible. An aluminum alloy that prints well in LPBF while delivering high strength and thermal stability could open new part-level applications where weight savings and temperature resistance matter, including fan blades, heat exchangers, and other components in aerospace, automotive, and data center cooling systems. The combination of rapid computational screening and experimental validation provides a pathway for future material development that is faster and more targeted than older trial-and-error approaches.

That said, the path from validated lab samples to industrial use requires further steps. Qualification for aerospace and automotive components will require extended testing, fatigue and creep studies, standardized powder production, and process-parameter optimization for specific machines. For now, the result is a concrete demonstration that machine learning can accelerate the discovery of additively manufacturable alloys with industrially relevant properties. The underlying research is documented in the paper titled "Additively Manufacturable High‑Strength Aluminum Alloys with Coarsening‑Resistant Microstructures Achieved via Rapid Solidification".

Sources:

Know something we missed? Have a correction or additional information?

Submit a Tip