New latent monomers enable on-demand solidification for 3D printing

Researchers at Ben-Gurion University of the Negev unveiled a latent monomer approach that keeps liquid printing materials stable for weeks and then triggers rapid polymerization on demand. The technique uses near-IR activated gold nanoparticles to locally convert an inactive storage form into a reactive monomer, offering hobbyists and makers new options for patterned curing, selective repairs, and post-print property tuning.

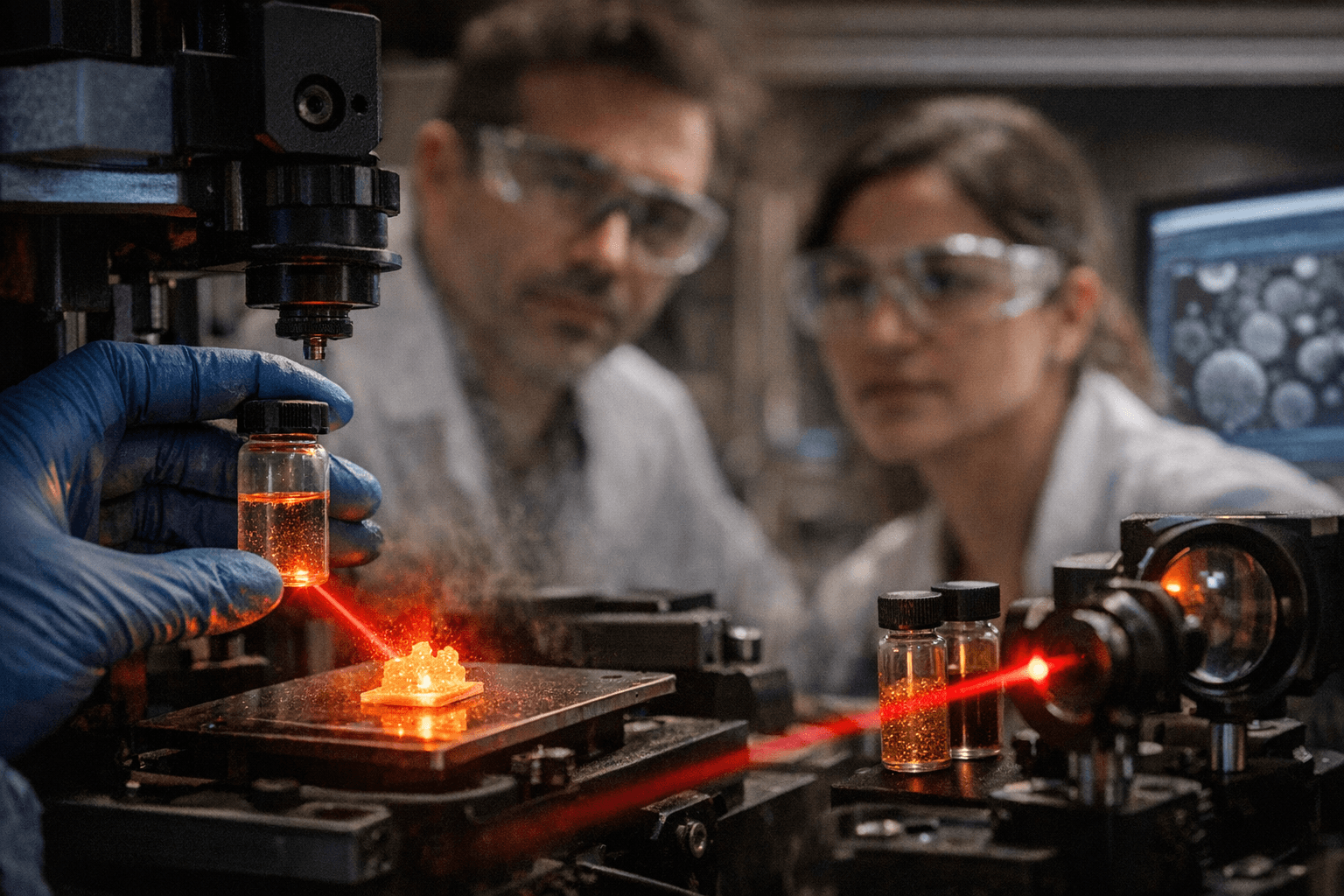

On January 5, 2026, researchers at Ben-Gurion University of the Negev described a polymerization strategy that could change how makers handle resins and post-processing. The system stores norbornadiene derivatives in an inactive quadricyclane form so that liquids remain shelf-stable for extended periods. When heat is applied locally—either directly or by illuminating embedded gold nanoparticles with near-infrared light—the quadricyclane reverts to the reactive norbornadiene, enabling ring-opening metathesis polymerization (ROMP) and an almost instantaneous hardening of the material.

The practical advantage for 3D printing is clear: you can print or shape with a liquid that behaves like an uncured resin and then selectively lock specific regions later. That selective activation allows patterned curing, targeted repairs, or staged hardening to produce parts that are soft where you want flexibility and rigid where you need strength. Because the triggering can be local and precise, it opens possibilities for post-print modifications without reprinting entire components.

Mechanistically, the approach leverages tiny gold nanoparticles dispersed in the liquid. Near-IR light heats those particles on a microscopic scale, driving the chemical reconversion and starting ROMP in the illuminated zones. The result is spatially confined polymerization: only illuminated regions harden, while surrounding material stays unchanged. This could support workflows where a single printed object becomes a multi-property composite after targeted post-processing.

For hobbyists and community makers, the outcome matters beyond the chemistry. Expect future materials and workflows that reduce wasted prints by enabling repairs and partial re-treatments, and that allow experimentation with multi-stage parts where toughness and flexibility are tuned after shaping. The research also points toward safer, more energy-efficient curing methods for coatings and small-batch production because activation can be driven by localized near-IR rather than whole-part ovens or broad-spectrum UV.

The work remains at a research stage, so ready-to-use consumer resins are not yet on shelves. Still, follow developments in experimental resins and post-processing tools: near-IR sources suitable for selective activation and formulations containing heat-converting nanoparticles are likely areas for hobby-level experimentation as commercial formulations catch up. For now, this latent monomer concept is a practical signal that on-demand, region-specific curing will become a realistic option for makers exploring advanced printing and repair workflows.

Sources:

Know something we missed? Have a correction or additional information?

Submit a Tip