New photocurable scintillator boosts 3D printing resolution for detectors

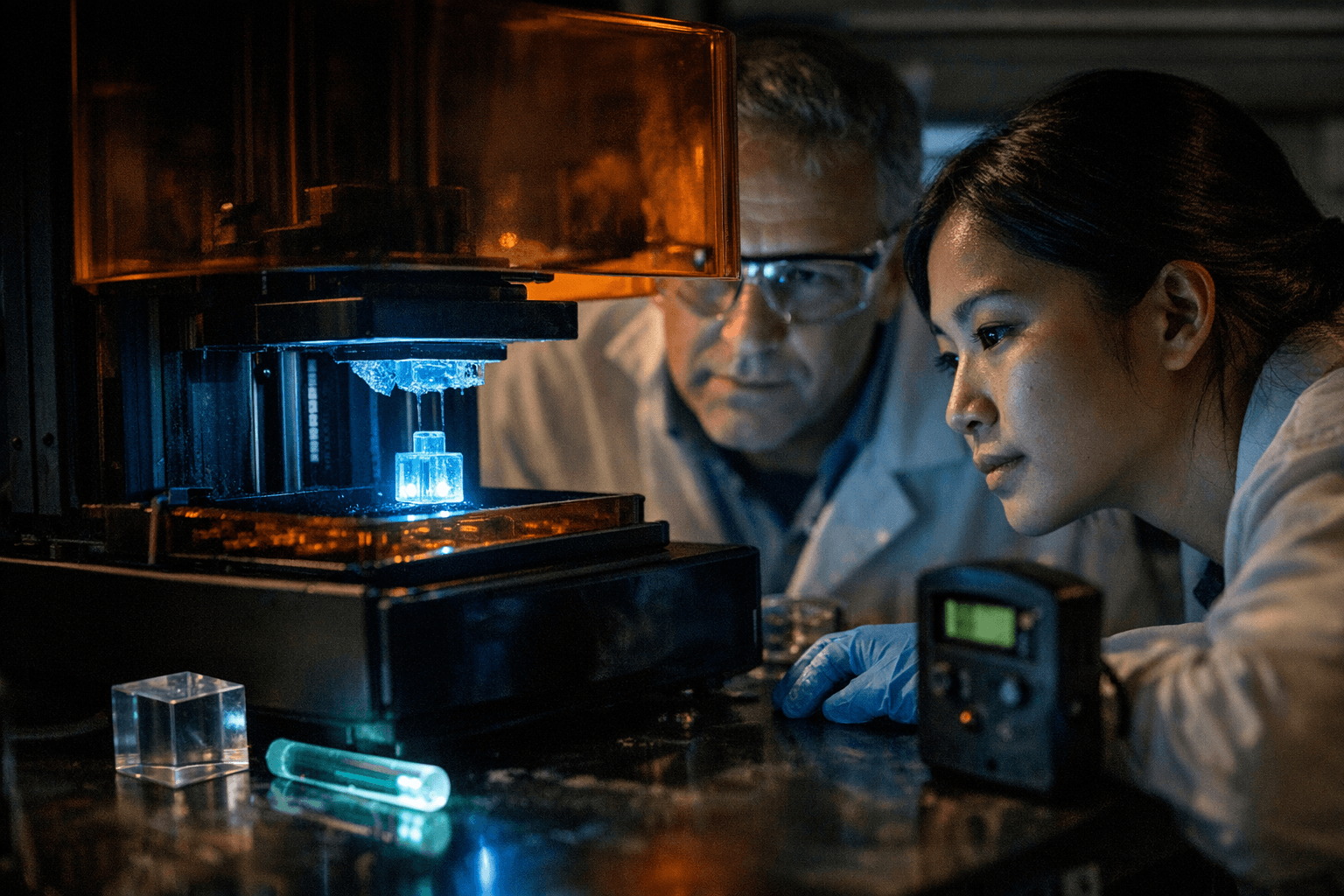

Researchers posted a paper on December 29, 2025 describing a photocurable plastic scintillator formulation that uses a tertiary dye, coumarin 450, to limit cure depth in vat photopolymerization. The approach dramatically improves print resolution on consumer 405 nm printers while preserving detector performance, a development that could open complex, printable detector geometries to hobbyists and small labs.

A team of researchers reported a practical path to higher-resolution, 3D-printed scintillators by adding a tertiary dye, coumarin 450, to a photocurable plastic scintillator formulation used in vat photopolymerization. Posted to arXiv on December 29, 2025 and indexed in the peer-reviewed Journal of Instrumentation, the work compares bulk photocured samples and DLP/405 nm printed parts with and without the dye and shows that modest chemical tweaks can reconcile optical detector chemistry with tighter printing control.

The key finding is that coumarin 450 acts as a cure-limiting dye: it limits the penetration of cure light without materially changing emission spectrum or light output. That control of cure depth translated into much finer printable features. Unsupported freestanding pillars as small as roughly 0.7 mm were printable, and supported features achieved approximately 0.1 mm resolution on consumer 405 nm printers. Those specs put small-run printed detector components well within reach of desktop resin machines.

Detector performance remained viable. Printed scintillators exhibited pulse-shape discrimination between neutrons and gammas, posted light output up to roughly 50 percent of EJ-200, and reached a pulse-shape discrimination figure-of-merit up to about 1.35 across the tested energy range. In short, adding the tertiary dye improved manufacturability while retaining the functional characteristics needed for basic neutron/gamma detection experiments.

The practical value is immediate for experimenters and makers who prototype detector architectures. Controlling cure depth allows researchers to tune printability independently from the core scintillating chemistry, enabling pixelated arrays, integrated optical features, and other complex geometries that were difficult or impossible with molding or machining. For small university labs, community groups, and advanced hobbyists, that reduces barriers to iterating custom optical paths and densely packed detector pixels.

Verify printer compatibility with 405 nm cure wavelengths and validate printed parts against known standards such as EJ-200 when assessing light output. Measure PSD performance in the relevant energy range for your application, and expect to iterate on post-processing and surface finish to optimize optical coupling. Follow-up work to watch for includes scaling to larger arrays, long-term aging and radiation hardness studies, and translation of the chemistry to different printing platforms.

This result aligns additive manufacturing and radiation detection more closely, expanding what a desktop resin printer can produce beyond models and fixtures into functioning components for radiation sensing and experimental testbeds.

Sources:

Know something we missed? Have a correction or additional information?

Submit a Tip