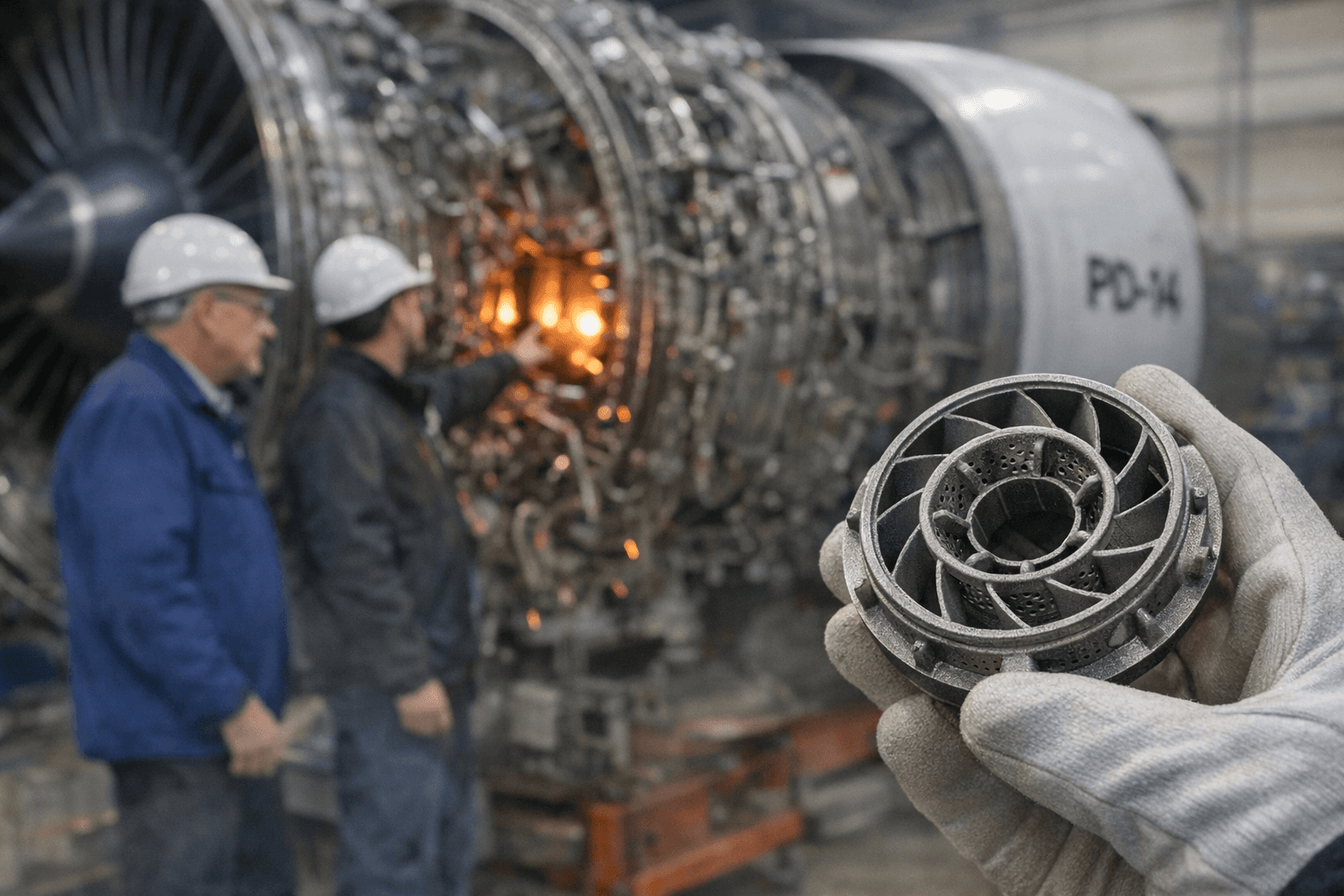

Russia’s UEC Certifies 3D‑Printed Hot Section Part for PD‑14 Engines

United Engine Corporation reported that an additively manufactured combustion chamber swirler passed certification and entered serial use in PD‑14 engine production on January 7, 2026. The move signals a major step for laser-based metal additive manufacturing in high-temperature aerospace hardware and may accelerate availability of advanced powders, post‑processing, and standards that affect the broader 3D printing market.

United Engine Corporation (UEC) announced on January 7, 2026, that an additively manufactured hot-section component — the combustion chamber swirler — has passed certification and is now in serial use on PD‑14 engines. The swirler is a critical high-temperature part in the engine hot section, and its certification for serial production marks one of the clearest demonstrations to date of laser-based metal additive manufacturing meeting aerospace quality and performance requirements.

UEC framed the achievement as part of a wider push to expand additive manufacturing across its engine families. The company highlighted an additive footprint that includes PD‑14, PD‑8 and PD‑35 engines and said its Center for Additive Technologies is scaling production methods, qualifying domestic alloys, and developing standards to enable wider adoption of AM in engine manufacture. Those efforts focus on production reproducibility, alloy availability and post-processing steps that are essential for hot-section hardware that operates under extreme temperatures and stresses.

For the 3D printing community this development matters beyond national or corporate headlines. Certification and serial use of a laser‑printed, high-temperature engine part provides concrete evidence that metal AM can meet the demanding inspection, heat-treatment and lifecycle requirements of aerospace applications. That in turn helps build a pipeline for advanced metal powders, accredited post-processing shops, and standardized testing procedures that hobbyists and small shops track when seeking reliable materials and services.

Practical implications are immediate and strategic. Verify supplier certifications and inquire about alloy qualification and post‑processing protocols when sourcing metal powders or contracting service bureaus. Expect increased demand for aerospace-grade nickel and cobalt alloys, stricter non‑destructive inspection regimes, and a premium for certified production runs. Over time broader availability of qualified powders and maturing standards may bring improved supply and clearer part qualification pathways for complex, high-temperature prints.

UEC’s announcement underscores a trend: industrial validation of metal AM in the most demanding environments often precedes trickle-down benefits for the hobby and small-business markets. Pay attention to which alloys and finishing processes receive formal qualification, and factor those developments into project planning and budgeting as the market adapts to certified, serial production of printed engine hardware.

Sources:

Know something we missed? Have a correction or additional information?

Submit a Tip