Two simple tools speed impeller swaps and protect pump bores

Two shop-ready tools make on-boat impeller swaps quicker and less risky, saving time and preventing damaged pump bores and shaft splines.

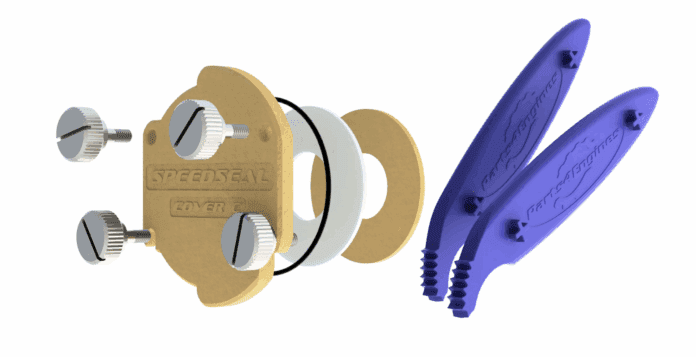

I tested two shop-ready solutions that make raw-water impeller maintenance faster and much gentler on pump hardware. The first is a Speedseal replacement pump cover built in brass with an O-ring seal, knurled thumb screws, and slide slots that let you remove and replace the cover quickly. The second is a Jabsco impeller puller that extracts stuck impellers without resorting to locking pliers that often score pump bores or ruin shaft splines.

The Speedseal cover shines where access is tight and conditions are sketchy. Its slide slots let you loosen and slide the cover free without fully withdrawing fasteners, so you can work with one hand or in the cramped space behind an engine. The knurled thumb screws replace fiddly bolts, saving minutes on each service and avoiding the awkward fumbling that turns a simple swap into a half day job. Because the cover is brass and uses an O-ring seal, it also reduces the chance of warping or misalignment that can lead to leaks when you torque things back up in a bilge environment.

Installation starts with good surface prep. Clean the mating surfaces thoroughly to remove old gasket material and corrosion, then lubricate the O-ring lightly so it seats without twisting. Compress the impeller vanes when installing to keep them from folding back on the shaft; a thin smear of lubricant on the vanes helps them slide into the bore without tearing. Work methodically: seat the impeller on the shaft, nudge the cover into the slide slots and hand-tighten the thumb screws before final snugging.

When an impeller is stuck, reach for the Jabsco puller instead of pliers. The tool is designed to engage and withdraw impellers evenly, minimizing the lateral force that marring the pump bore and splines. Match the puller size to your pump model; common Jabsco sizes fit the small to medium raw-water pumps found on most pocket cruisers and trawlers. Sources include major marine parts suppliers and Jabsco dealers, and the replacement cover and puller are available through specialist outlets such as Parts4Engines and Speedseal channels. Both items are modestly priced and aimed at the DIY budget.

The critical takeaway is preparation and gentle extraction. Clean mating faces, lubricate O-rings and vanes, compress the impeller during install, and use a dedicated puller for removals. That combination keeps pump bores unmarred and shaft splines intact, which means fewer surprise repairs on passage.

Our two cents? Spend a few bucks on the right cover and a puller, practice the prep steps ashore, and your next impeller change will feel more like routine maintenance and less like emergency surgery.

Sources:

Know something we missed? Have a correction or additional information?

Submit a Tip